In an increasingly computer focused society, businesses are faced with the challenge of continually mastering new techniques and programs to keep pace with the market. Even in industries where efficiency has always been a primary focus, professionals can find it difficult to adapt to the rapid development and expansion of data driven technology. While education can be time consuming and expensive, the benefit of utilizing modern drafting software is incomparable.

At TMS a significant portion of our projects are focused on solving malfunctions within complex production systems. Every second that a line is stopped costs our customers dearly, and nothing has saved us more time than AutoCAD. By enabling our design team engineers to fully map a system digitally, the time consuming and sometimes dangerous trial and error of assembly is removed from the work site. A single technician with a computer can identify, investigate and plan for the majority of obstructions and potential risks. AutoCAD drawings keep track of the finest details, even accommodating for proper gap space between welds.

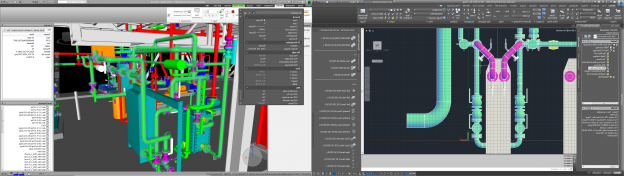

Understanding how an object can be maneuvered through a space is vital in the complex systems of production plants. Work sites are often congested, difficult to access and constantly changing. Knowing which objects can be brought into an area allows our technicians to do all possible prefabrication work in our own shop. 3D drafting gives our team incredibly accurate plans from which to craft custom parts and makes planning projects easier. With individual pieces of a project labeled and categorized, we can create weld schedules to ensure each person is making the correct welds at the right time. With prefabrication done in our work shop, the time spent on site is shorter. This not only saves money but is less intrusive to the customer.

The vast majority of our customers continue to operate while maintenance is performed. Working in the midst of a live industrial production system is inherently dangerous. The safety and success of a project relies on our complete understanding of the entire system, not solely the project in focus. AutoCAD’s layering function has drastically improved our ability to model the individual systems within a work site. With layered drawings, a 3D model is created of each system with respect to its spatial relationship to the rest of the plant. The drawing can be viewed in its entirety, or we can select to view 3 of 10 lines. The team has a precise diagram by which they can recognize what materials are passing through the work space. With this information we can make decisions on site about what techniques and materials are safe to use around a specific system. Layering also presents us with the opportunity to examine the interactions between systems without the visual obstructions that may exist on site.

Our dedication to understanding the entire system through focused study and complete modeling has not changed since the days of pencil and paper drafting, but the integration of AutoCAD has revolutionized the speed at which we work. The maintenance of a skilled computer drafting team is undeniably essential to mechanical contracting in the 21st century.